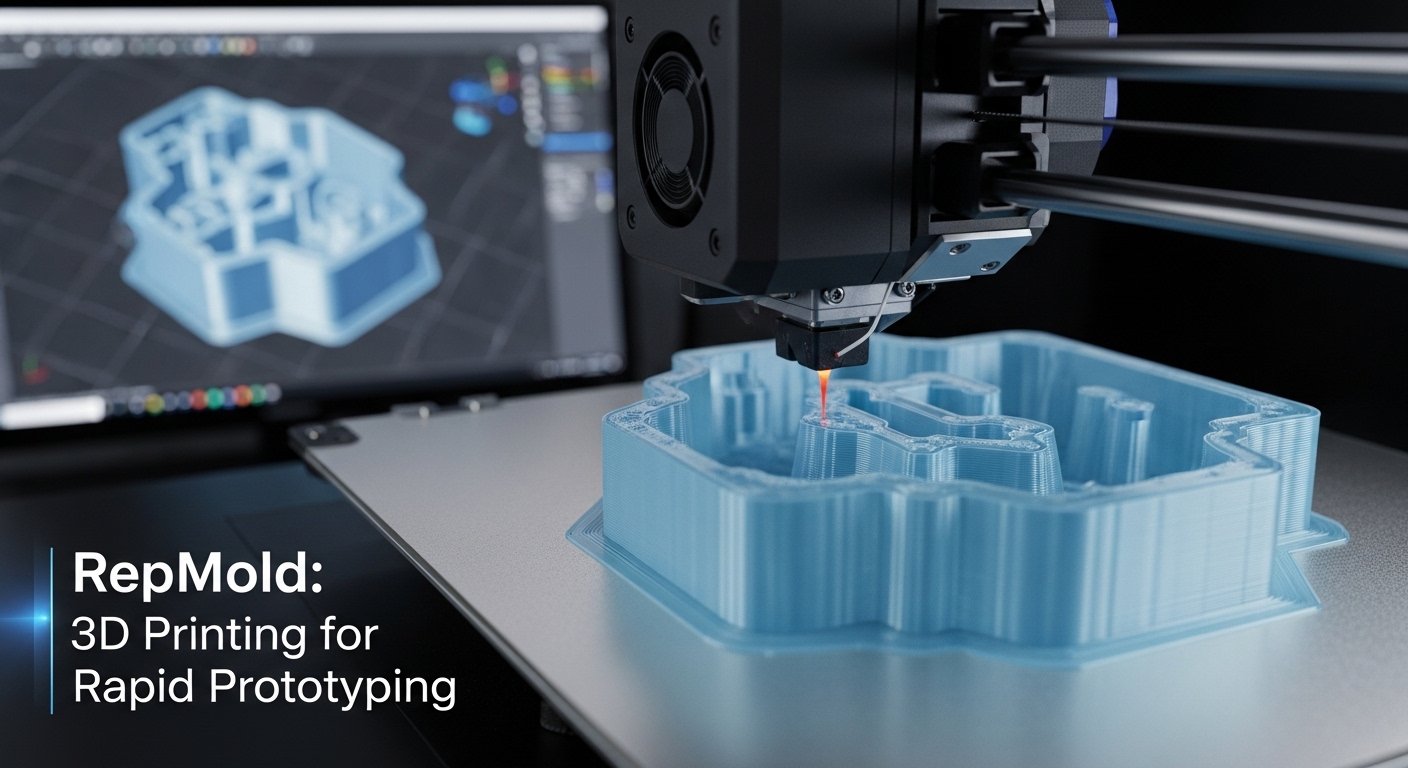

In today’s fast-paced world, the ability to quickly transform ideas into tangible products is essential for success. Enter RepMold—a revolutionary approach that combines 3D printing with rapid prototyping. This innovative technology not only streamlines the design process but also opens up new possibilities for creators across various industries. Whether you’re an engineer looking to refine a product or a designer aiming to bring concepts to life, RepMold offers solutions that can elevate your projects and significantly reduce time-to-market. Let’s dive deeper into what makes RepMold such a game-changer in the realm of prototyping and how it can benefit your business like never before.

Understanding 3D Printing and Rapid Prototyping

3D printing has revolutionized the way products are designed and developed. This technology enables the creation of three-dimensional objects from digital files, layer by layer. The process is efficient and customizable, allowing for intricate designs that traditional methods may struggle to achieve.

Rapid prototyping refers to quickly transforming concepts into tangible prototypes using 3D printing. Designers can iterate their ideas in real-time, making adjustments on-the-fly based on feedback or testing results. This agility accelerates product development cycles significantly.

Moreover, rapid prototyping helps in minimizing material waste compared to conventional manufacturing processes. As companies explore innovative solutions, they find that 3D printing meets diverse needs across various sectors—from automotive to healthcare—enhancing creativity while reducing costs and timeframes associated with bringing new products to market.

Applications of RepMold in Various Industries

RepMold is making waves across numerous industries. Its versatility allows for rapid prototyping that meets diverse needs.

In the automotive sector, engineers use RepMold to create intricate parts quickly. This accelerates design cycles and enhances innovation.

The medical field benefits significantly as well. Custom prosthetics and surgical instruments can be produced with precision, tailoring solutions to individual patients.

Consumer electronics are another prime area of application. Designers can iterate on product concepts swiftly, reducing time-to-market for new gadgets.

Even in aerospace, where every ounce matters, RepMold facilitates lightweight component development. This fusion of performance and efficiency is crucial in such a competitive market.

From fashion prototypes to architectural models, RepMold adapts seamlessly across various disciplines. The potential applications are virtually limitless as industries continue embracing this technology’s advantages.

How RepMold Saves Time and Money for Businesses

RepMold significantly cuts down prototyping time. Traditional methods can take weeks or even months to create molds and parts. With RepMold, businesses can produce prototypes in a matter of hours.

This rapid turnaround allows companies to test designs quickly. They can iterate on ideas without the long wait times typically associated with production processes.

Cost efficiency is another crucial benefit. Using RepMold reduces material waste compared to conventional manufacturing techniques. This not only saves money but also supports sustainability efforts.

Moreover, lower labor costs come into play as fewer workers are needed for complex tasks. Businesses can reallocate resources, focusing on innovation rather than tedious manual labor.

The financial savings extend beyond just production costs; faster market entry means quicker returns on investment. Companies leveraging RepMold stay competitive by bringing products to consumers sooner than others in their industry.

Case Studies of Successful Implementation of RepMold

One notable case study involves a leading automotive company that utilized RepMold for their prototype parts. By switching to this innovative technology, they reduced the time taken from design to production by nearly 50%. The lightweight yet durable prototypes allowed for extensive testing without compromising on quality.

In another instance, a consumer electronics startup embraced RepMold to create intricate casing designs. This approach enabled them to iterate quickly based on user feedback. The rapid turnaround significantly shortened their product launch timeline.

Additionally, a medical device manufacturer implemented RepMold to develop custom surgical tools. These highly specialized prototypes were crafted with precision, enhancing functionality and safety in real-world applications. Their ability to produce complex geometries led to improved patient outcomes and satisfaction.

These examples illustrate how diverse industries are leveraging RepMold’s capabilities for innovative solutions. Each success story highlights the transformative power of effective prototyping practices.

Future Possibilities and Advancements in RepMold Technology

The future of RepMold is brimming with potential. As technology advances, we can expect even faster printing speeds and enhanced material capabilities. This could revolutionize the way prototypes are created across various sectors.

Imagine integrating artificial intelligence into the design process. AI could optimize designs for functionality and cost-efficiency, streamlining production like never before.

Moreover, advancements in biocompatible materials may open new doors in healthcare applications. The ability to create custom implants or prosthetics tailored to individual patients would be a game changer.

Sustainability also plays a crucial role in the evolution of RepMold technology. Innovations aimed at reducing waste during production will likely become more prominent as environmental concerns grow.

These developments indicate that RepMold isn’t just keeping pace; it’s poised to lead the charge toward smarter, more efficient prototyping solutions.

Conclusion: Embracing the Future of Prototyping with RepMold

The world of prototyping is evolving rapidly, and RepMold stands at the forefront of this transformation. With its advanced 3D printing capabilities, it offers unique solutions that cater to a variety of industries. Businesses can leverage its efficiency and cost-effectiveness to streamline their processes.

The future is bright for RepMold as technology continues to advance. As more companies adopt these innovative practices, we can expect even greater developments in material science and design flexibility. This will further enhance the potential applications of RepMold across multiple sectors.

Embracing such cutting-edge technologies not only positions businesses for success but also paves the way for creative innovation. The journey with RepMold represents more than just a tool; it’s about reimagining what’s possible in product development and bringing ideas to life faster than ever before.